Products > TH-Series Heat Shrink Tubers

TH8001-Plus Dual Station Terminal Shrinkable Tuber

PRODUCT SUMMARY

Recommended for mass production of terminal tube shrinking, especially for thick terminals. Comparing to the classic H8001/8002 versions:45% shorter, 20% more efficient

Classic shrinkable tuber for terminals. Compact design,

two stations work simultaneously or alternatively with high efficiency

Infrared heater: more energy savings & better temperature stability (crucial to tube shrinking)

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

Piggyback custom wire holders: fast changeable

Support various heater sizes

Support single station version

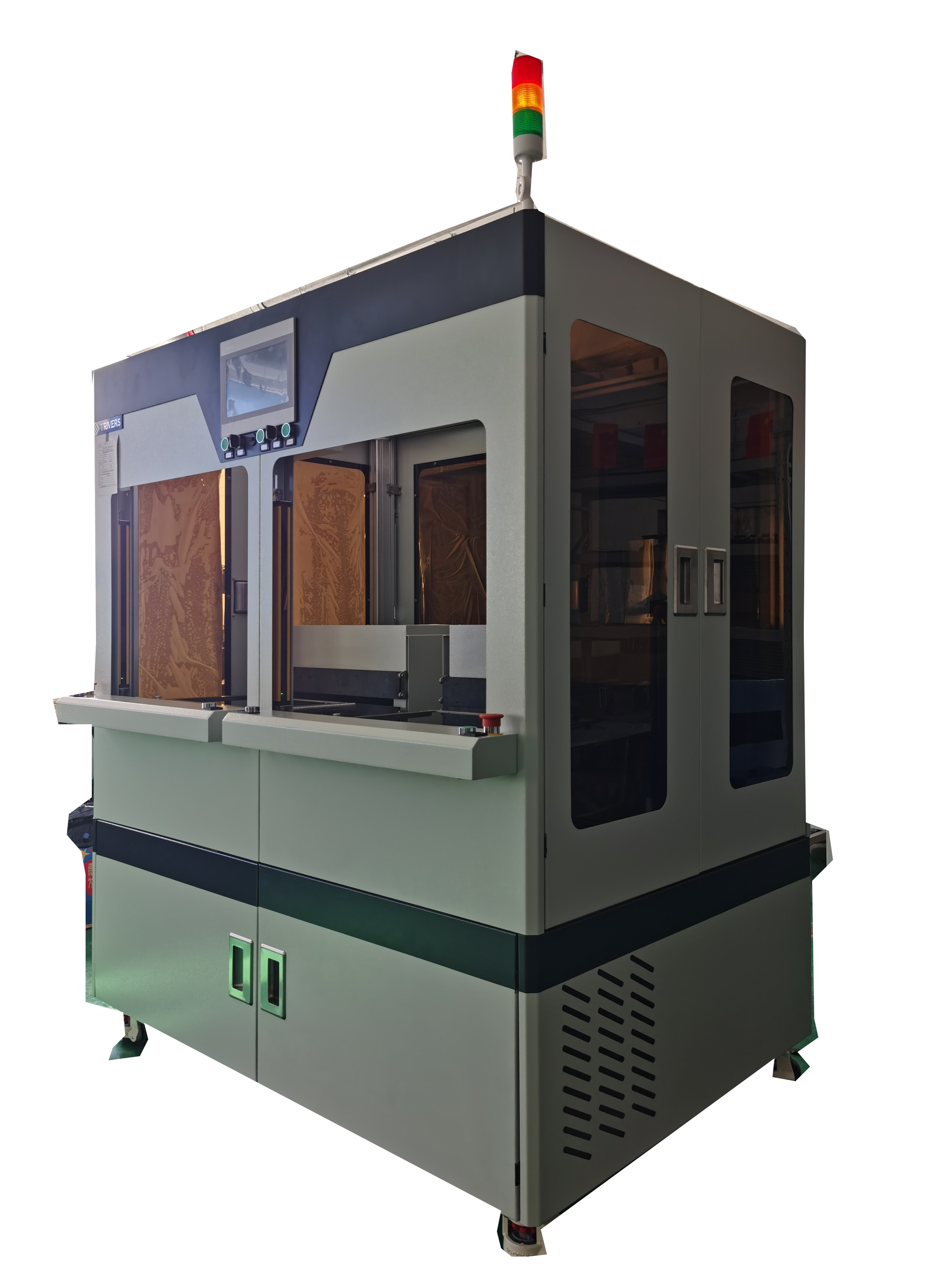

TH8001-Pro Thick Terminal Shrinkable Tuber

PRODUCT SUMMARY

Machine specialized for EV cables with thick/irregular terminals or multi-tubes. Dual stations working simultaneously or alternatively to achieve high efficiency. Extra-large heater to accommodate large terminals and thick cables.

Heater shield for heater stability & operator comfort

Infrared heater: more energy savings & better temperature stability (crucial to tube shrinking)

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

Piggyback custom wire holders: fast changeable

Rich options:

Adjustable heater space: no re-setup for product change

Cooling lift: reduce cooling time significantly

Even heating zone: increase process capacity by 25%+

Dual heating zones: great for multi-tube shrinking

TH8002H Digital Terminal Wire Shrinkable Tuber (Single station)

PRODUCT INFORMATION

TH8002H is a single-station version of TH8001-plus, but the size of the heat shrinkable tube is wider. The following requirements can be considered for this model:

The length of the heat shrinkable tube exceeds 75mm and the diameter exceeds 25mm or

It meets the application range of TH8001-plus but the output is not as large and meets more limited budget requirements

TH80-OLE1 Online Shrinkable Tuber

PRODUCT SUMMARY

TH80-OLE1 - Regular Wire Version

Retractable pointy-mouth heater. Best suited for operation in small & complicated spaces.

Top pick for on-line shrinkable tubing: pointy retractable mouth easy to access small space, cylindrical heater better in stability and efficiency

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Versatile control panel positions and mounting methods for any mobile applications

Unique temperature automatic calibration with special Trivers measuring kit

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, sequence control, MES interface, sync with ultrasonic welder

TH80-OLE2 EV Cable Online Shrinkable Tuber

TH80-OLE2 Thick Cable Version

PRODUCT SUMMARY

Retractable pointy-mouth heater. Easy to setup, high mobility.

Large sized cylindrical heating zone with stable temperature and higher efficiency, particularly good for thick EV cables requiring accurately uniform shrinking

Retractable pointy-mouth heater with detached control unit, very mobile for online applications

Open fixture setup zone, easy to install and change

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Unique temperature automatic calibration with special Trivers measuring kit

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, sequence control, MES interface, sync with ultrasonic welder

TIV6 Portable Hot Air Shrinkable Tuber

PRODUCT SUMMARY

High pressure & temperature air gun, even-temperature shrinking cavity, strong penetrative air jet, best suited for thick and dense wires

Hot air tube shrinking suitable for:

Multiple wires and tubes in cluster

Requirements more on machine budget than shrinking temperature stability

Portable pointy heater, good for mobile use and one piece flow process

esign of even jet flow outlet to improve heater temperature uniformity

Dedicated Trivers shrinking control system: enhanced temperature stability, scan input, kanban manager, process data display & storage

Optional large sized, fast changeable heaters

Custom wire holders

TIV8 Robotic Heat Shrinking Tuber (Space-saving)

PRODUCT SUMMARY

Retractable pointy-mouth heater: directional & angular adjustment, best suited for operation in small & complicated spaces

Wire length for ultrasonic welding significantly reduced due to close-in small head

Slim body with precision motion control to reach target in narrow space on Kanban

Enclosed cylindrical heating zone for even temperature, energy savings and faster takt

Modular design: Heater/control/fixture are all detachable & customizable, and can be quickly changed

Supports online heat shrinking process and mobile heat shrinking applications

Supports sequence control & one-piece flow

Supports scan input and ultrasonic welder link

Smart calibration & SCADA support

TH80-JT Desktop Thick Cable Shrinkable Tuber

PRODUCT SUMMARY

Portable desktop shrinkable tubing, mainly for thick wire harness heat shrink tubing processes, and other complex processes

Movable heater with stationary holder for heavy cables to ensure operability

One-button operation of automatic feeding, heating, returning & cooling wire

Supports one-piece flow

Supports RS485 communications

Custom design of wire holders & heaters

Optional Network & SCADA

TH80-JT-Plus Guide-rail Thick Cable Shrinkable Tuber

PRODUCT SUMMARY

TH80JT-plus is a mountable guide rail version of the TH80-JT to scan and heat shrinkable tube. It is suitable for super long heat shrinkable tubing and can also be used for the continuous heating of multiple thick heat shrinkable tubes.

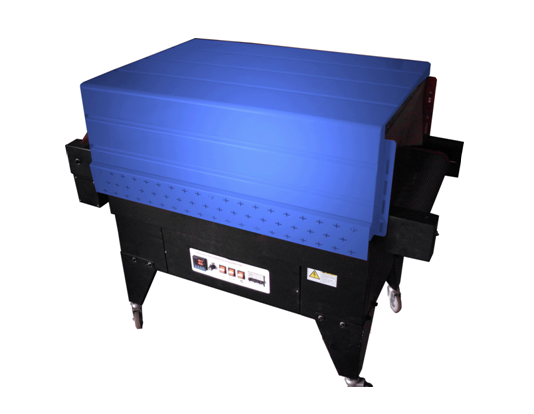

TH801-Lite Conveyor Shrinkable Tuber (Regular version)

PRODUCT SUMMARY

Basic model recommended for continuous and mass production of tube shrinking mainly for splice wires

Conveyors continuously transport wires through heater and drop tube shrunk wires into collector after cooling

Different heater sizes to choose from for tube variety

Supports wire diameter up to 10mm

Options of side conveyor, a ‘toothless’ main conveyor for very thin wires and ring terminal fixture etc

Serial link for data communications

TH801-Plus Enhanced Conveyor Shrinkable Tuber

PRODUCT SUMMARY

Recommended for continuous mass shrinking process of splice wires, high end model

Most powerful conveyor shrinkable tuber model, the same thick cable handling, higher process efficiency

Longer heating zone + higher heating temperature + turbo cooling: boost 35% production efficiency

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface, semi-auto temperature calibration

Narrow & wide heaters optional

TH801T Conveyor Shrinkable Tuber for Terminal Wires

PRODUCT SUMMARY

Conveyor shrinkable tuber equipped with special chain to hook terminals and special belts to hold wires firmly. Terminal wires now can have continuous shrinking on conveyor with higher efficiency and production volume.

Process terminal wires with special conveyors, excels traditional conveyor shrinkable tubers

Patented openable conveyor pair, easier to operate and better to handle short wires

Chain conveyor for terminals: position adjustable & fixture fast changeable

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface, semi-auto temperature calibration

Various sized heaters optional

Various standard and custom fixtures

TH8010 Mass Production Air Jet Heat Shrink Tuber Machine

PRODUCT SUMMARY

The air-jet heat shrinkable tube heater TH8010 applies air-jet heat shrinking technology.

On a high-capacity conveyor belt, the batch of heat-shrinkable tubes are sent through the heating zone to complete the heat shrinking.

The height, blowing direction and temperature of the shrinkage furnace can be adjusted freely, and tooling can be customized.

The TH8010 provides low cost, high output operational efficiency with where there are no precise positioning requirements for heat shrinking single-wall tubes.

TH8080 Portable Flip-lid Shrinkable Tuber

PRODUCT SUMMARY

Most versatile, portable and economical shrinkable tuber, suitable for both splice and terminal wires, easy to carry around

Smart energy saving and safety: open/close lid to turn off/on heater; lid locks in heating and heater turns off at timeout

Float lid design, operation with little fatigue

Very simple settings and operation with Trivers powerful dedicated control core

Wide heater optional

Custom design wire holders available

TH80-DP Tube Shrinking and Press Machine

PRODUCT SUMMARY

Efficient and effective method ensure full coverage and tight seal on terminals.

Independently adjustable press heads to adapt terminals position/contour variation

Automatic auxiliary holder to prevent terminals from pop-up

Shrinking and pressing at the same time on different stations to achieve best efficiency

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Piggyback custom wire holders: fast changeable

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

TH80JT-DW-ZC Shrinking & Bending Machine

PRODUCT INFORMATION

Tube shrinking and subsequent bending combined in one machine without manual interference. Perfectly solves timing issues between shrinking and bending when they are handled on different machines or tools.

Supports 3D bending with maximum 3 bending angles

Precise bending without press marks, adjustable compensation of bending springback

Shrinking and bending at the same time on different stations to achieve best efficiency

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

Supports custom design of bending fixtures and heaters

Supports single station version

TH80JT-F Desktop Versatile Shrinkable Tuber

PRODUCT SUMMARY

Versatile shrinkable tuber handles both splice and terminal wires with simple holder adjustment. Desktop installation is easy to transport or relocate.

Handle both splice and terminal wires, compact single station with flexibility:

Short tubes horizontally placed head to head: double process capacity

Long tubes vertically placed: shrink up to 300mm long tube

Automatic heater shield to improve heater stability and operator comfort

Infrared heater: more energy savings and better temperature stability (crucial to tube shrinking)

Piggyback custom wire holders: fast changeable

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

Optional wide heaters, custom wire holders

TH80JT-Plus-DW Duplex Versatile Shrinkable Tuber

PRODUCT SUMMARY

Versatile shrinkable tuber handles both splice and terminal wires with simple holder adjustment. Dual station delivers not only higher efficiency but also an extra feature of horizontal scan mode which heater can move across two stations to process very long tubes.

Dual stations with configurable routes & varying speeds deliver higher efficiency & flexibility Great for complex shrinking, ultra-long or multi-tube shrinking:

Short tubes horizontally placed head to head: double process capacity

Long tube vertically placed: shrink up to 300mm long tube

Horizontal scan mode: shrink up to 800mm long tube

Heater shield to improve heater stability & operator comfort

Infrared heater: more energy savings & better temperature stability (crucial to tube shrinking)

Piggyback custom wire holders: fast changeable

Dedicated Trivers control system: scan input, kanban manager, process data display & storage, MES interface

Custom wire holders, rich options